LET’S FIGURE OUT WHAT’S REALLY GOING ON…

First 30 minute call is complementary

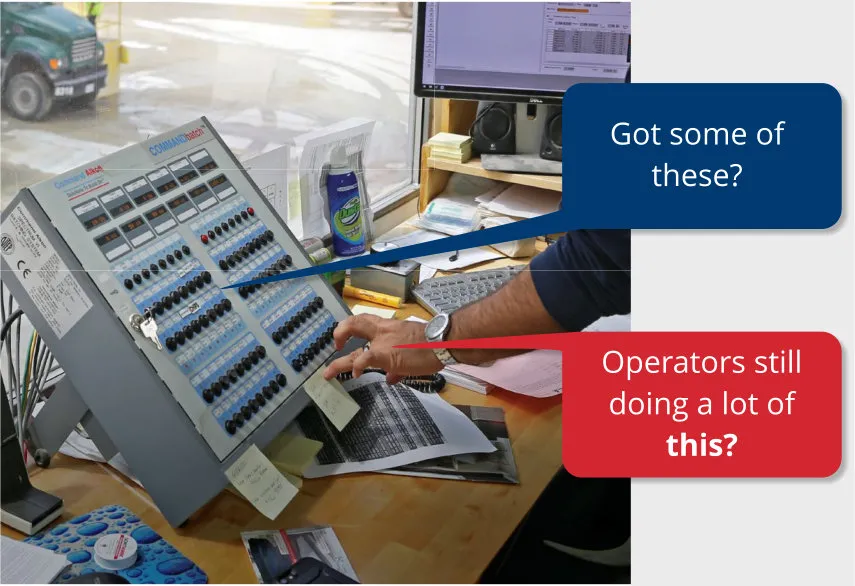

As an expert with the world’s most deployed plant automation solution I know that manual operation creates opportunities for mistakes and slows production. During this season of maximum production, a health check of your plant and automation equipment (along with operator coaching) can shave valuable seconds off of each load.

Tuning software and the plant takes experience and skill. Let my 30 plus years of experience work for you. Contact me to schedule a 30 minute review of your operational bottlenecks at a special introductory rate and make a plan to improve.

DATA CONUNDRUMS?

Got lots of data and reports, but not sure how to read it or it doesn’t seem to add up? Let me help you identify and consolidate what you have now to understand your results.

MOISTURE MEASUREMENT PROBLEMS?

Getting moisture sensors connected properly and then calibrated can be challenging. With the variety of moisture sensor manufacturers getting everything working correctly requires a process that is used company wide. It’s a journey but can improve your concrete consistency.

MOISTURE MEASUREMENT PROBLEMS?

Getting moisture sensors connected properly and then calibrated can be challenging. With the variety of moisture sensor manufacturers getting everything working correctly requires a process that is used company wide. It’s a journey but can improve your concrete consistency.